As RYCON Constructions continue its 20 year anniversary celebrations, we sat down with Gerard Ryan, Director, to reflect on his company’s journey and to gain insights into the changes he has witnessed within the construction industry over the past two decades.

Where and what was RYCON’s first project?

RYCON’s first project was for a family friend. A raise and restump renovation of a Queenslander in Kates Street, Morningside. The renovation was worth approximately $200,000, which back in 2003 was a good-sized project.

Image: RYCON Constructions, Morningside Project

How long were you in the construction industry before establishing RYCON Constructions?

I obtained my apprenticeship in 1987 while completing my final year of high school. The following year, in 1988, I began my career as an apprentice carpenter and joiner with Civil & Civic, Australia’s largest construction company, now known as Lendlease.

My first project was the new Police Headquarters in Roma Street in Brisbane, and I worked on this job for two years from start to finish. I continued to work with Civil & Civic for 13 years on many major Brisbane projects.

In 1999, I moved on to work for a private home builder, Peterbuilt Homes, as a Construction Manager, where I learned about architectural homes.

After obtaining my Medium Rise Builder Licence in late 2002, I left my role as Construction Manager and began RYCON Constructions in January 2003.

How many staff did RYCON start with, and how many do you have now?

RYCON Constructions began with just me and two subcontractor carpenters. As our operations grew, I expanded the team and employed two of my own carpenters. Over time, our company has continued to grow and expand into commercial projects. We now proudly work with a dedicated team of 14 employees.

Image: (almost) All of the RYCON team!

What are the most significant changes you have seen in the industry? How have materials changed?

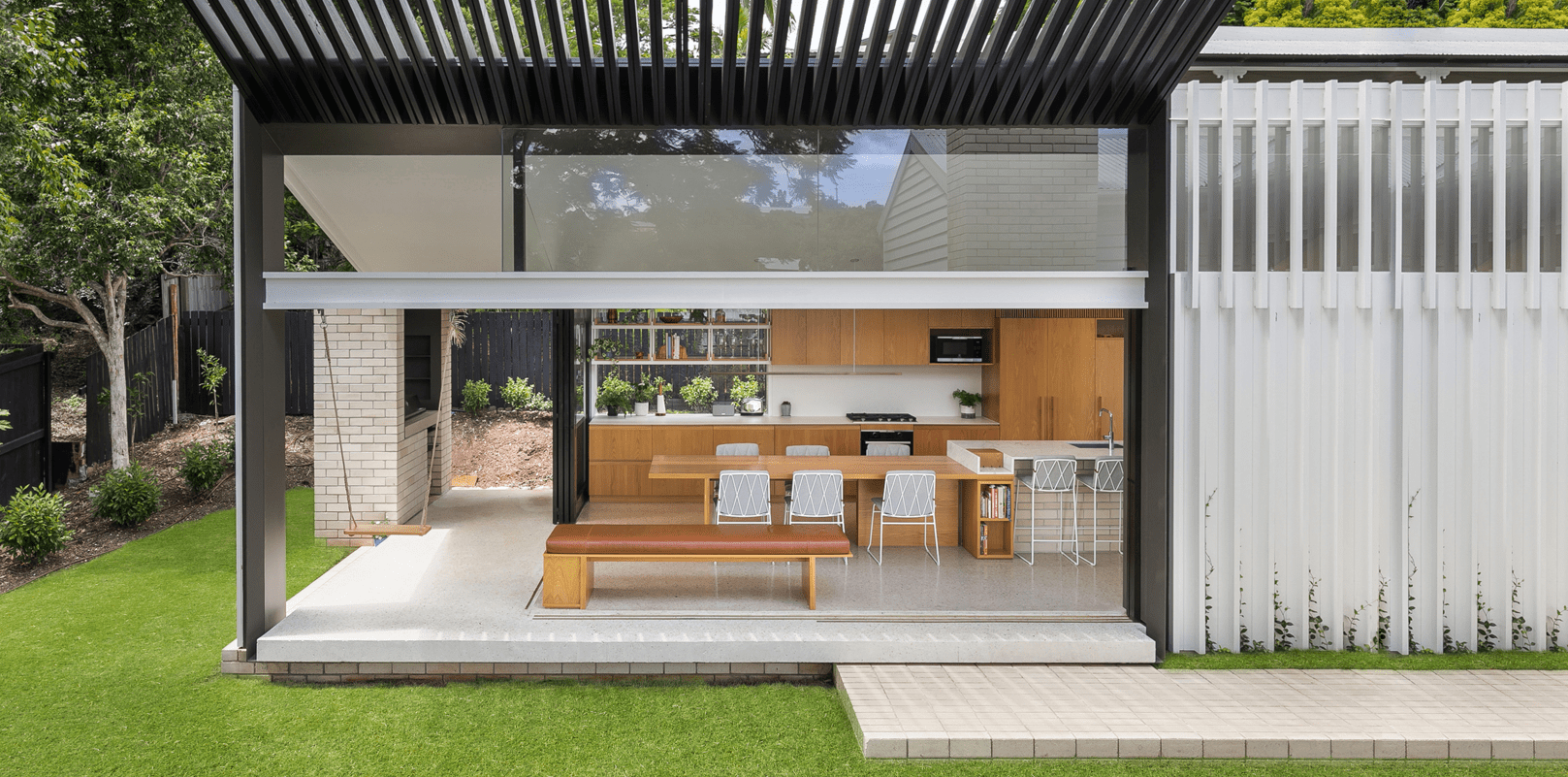

The style and type of homes have changed immensely over the last 20 years. Homes are now more of a design showcase with many more features, making projects more challenging to build as they take extended consideration and much more coordination. This is mainly due to the intricate detailing of cabinets, feature lighting, and lighting automation.

Window and door design choices have also changed by increasing size but with minimalist features. For example, sliding doors are now floor-to-ceiling and often stack back into door cavities, allowing for a cleaner indoor and outdoor open living plan. They’re ideal for our Queensland climate and lifestyle and are a feature I personally love seeing in our new home builds.

Image: RYCON Constructions, Paddington Project

How has environmental sustainability played a role or dramatically evolved in your 20 years with RYCON?

From the early days, I always encouraged the team to recycle materials wherever possible. Building sites can accumulate a lot of rubbish, and I have always insisted on keeping our worksites clean and clear. Throughout RYCON’s 20 years, we have maintained a commitment to recycling materials whenever it is viable to do so. We also actively source recycled materials to assist us in completing projects. Recycled timber can provide some stunning features in homes when specifically sourced. I have encouraged the use of solar power and managing dust suppression and water waste on all our projects across both the residential and commercial teams.

What are some design features that have stood the test of time?

Tile colours and the size of tiles have entirely changed. Top colour choices are now more earthy and natural in a tone that takes on a European look, whilst the size of tiles has increased to a larger format.

Clear-finished timber joinery and doors are still in fashion. Still, they are more commonly matched with concrete and steel materials for a more industrial look.

Image: RYCON Constructions, Ascot Project

What are some of the most challenging blocks you have worked on, and why?

Our most demanding projects generally fall into two categories:

Projects involving steep slopes and limited street access often present challenges. Delivery of materials, parking for tradespeople, and coordinating them on-site as they often require their vehicles close by, are just some of the considerations. Complex blocks, like our current project at Dutton Park on the river, have limited storage options for new materials arriving and the disposal of old materials through skips. On this job, to access the steep riverfront block, we used barges to bring in machinery and materials.

Projects outside the Brisbane CBD, such as our Noosa and Boonah projects, require meticulous planning for material delivery. We also had to ensure that the subcontractors’ works were prepped and ready for them to complete when they arrived on-site due to travel costs and travel time.

These projects can be less productive as employees don’t arrive on site as early as usual and want to leave early to get home at a reasonable hour. When a job is 1.5 hours away, it is close enough to home so you don’t have to stay nearby overnight, but too far to drive every day for long periods.

Image: RYCON Constructions, Dutton Park Project

Throughout all the price rises in the last couple of years due to unprecedented world events, how has RYCON Constructions continued to build and successfully remain at their A-game when many construction businesses are going bust?

We have always put time and value into nurturing our relationships with subcontractors and suppliers, and this has enabled us to work together and confirm price holds before entering a contract. This has also allowed us to provide clients with a fixed price and honour it through to completion.

The result is all parties are happy and we can maintain our margins and make a profit. It has not been easy, given the turbulent state of the sector, but one we have focused on closely to ensure we are always doing exactly what we say we will do.

What old school skills do you still use that the younger guys give you a hard time about?

Not that the guys give me a hard time, but I put a significant focus on site set-out and the use of good profiles that are clearly marked and colour coded to avoid confusion. A good profile is like a storybook that everyone on the site should be able to read and understand.

As mentioned earlier, I also expect a very clean site and work areas, making for a more efficient and happier workplace. The standards you walk past are the standards you accept, and I have always encouraged my team to be aware of this.

More from the blog

Jonah’s Journey with RYCON Constructions

One of our key values at RYCON Constructions is investing in our people. Our owner and Director, Gerard Ryan, has enjoyed a stellar 30+ year career in the Brisbane building industry, and he knows...

Building for Brisbane’s Climate: Tips for Comfortable Living

Image: Brunswick Street, New Farm – 7 units to 4 townhouses project. Learn more about the project here. Brisbane’s climate brings long, warm summers and mild winters, making it a fantastic place to...

Luxury Builds: Favourite Features From Our Recent Projects

Image: Brunswick Street – New Farm townhouse project. Learn more about the project here. At RYCON, we’ve had the privilege of constructing and renovating truly remarkable luxury homes. We look back...